Overcoming Inventory Stagnation Through Dynamic Demand-Based Ordering Decisions

Posted by | Fuld & Company

A global cosmetics brand facing inventory stagnation wanted to introduce better analytics to inform their decision-making regarding stock.

Objective

To increase demand and create an optimal price model, with the aim of maximizing sales and developing a dynamic decision-making system that could optimize the store inventory.

Approach

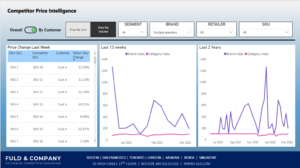

- Collected weekly price and sales data, including total category sales and average product prices from 3P data sources. Also considered holidays and events as exogenous variables.

- Leveraged machine learning algorithms (such as OLS and SARIMAX) to predict brand demand and optimal pricing to maximize sales.

- Leveraged model equations to set up a Markov Decision Process to evaluate end-of-week inventory for each store and defined a more dynamic demand-based re-ordering algorithm that considered the company’s order lead time.

Outcome

- After 11 weeks of change management efforts with the brand’s leadership, the company trial tested the model at five stores in New York, Florida, California, Washington, and Illinois.

- The stores cleared their stagnating inventory within five to nine weeks, and the four-week average value of inventory at these stores dropped by US$1.8 million cumulatively. The stores did not report any stockouts during the test period.

Algorithms Used: Econometric models such as OLS and SARIMAX and the Markov Decision Process

Tools

Tags: case study, Data analytics, luxury